Automation

- Application Solutions Overview

- Automation

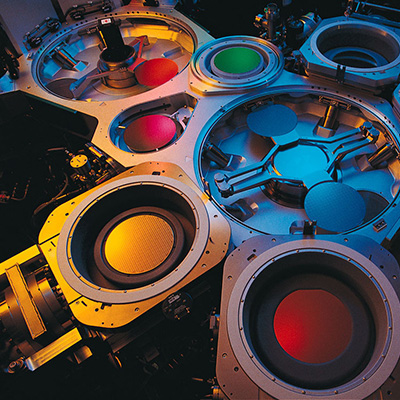

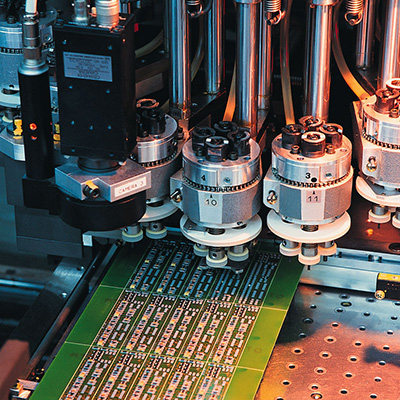

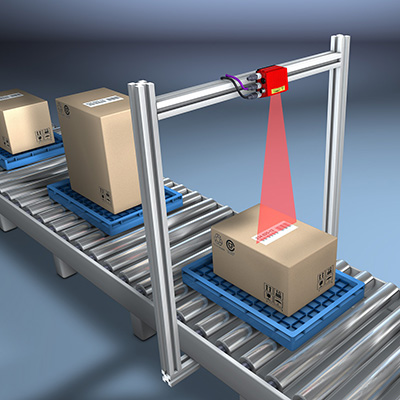

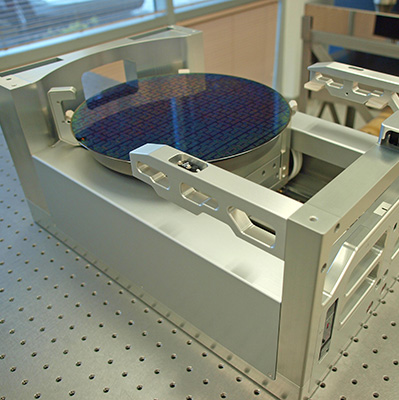

Automation Motion Solutions

Allied Motion’s servo motors, torque motors, motion controllers and drives, and encoders deliver the reliability and precision needed in modern advanced automation systems as found in semiconductor and electronic test, assembly and packaging equipment.