EnduraMax™ Brushless Motors with Drive

- Brushless Motors

- Brushless DC Motors with Drives

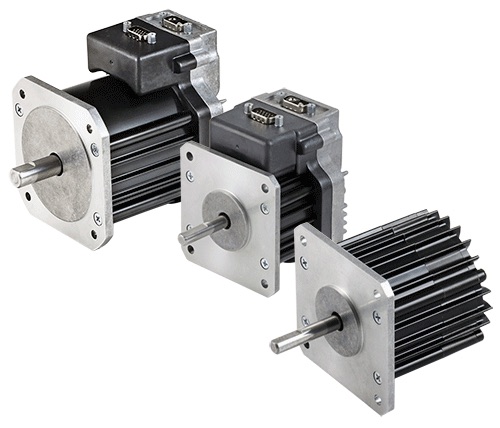

- EnduraMax™ Brushless Motors with Drive

EnduraMax™ Brushless Motors with Drive

Allied Motion's EnduraMax brushless DC motors include integrated drive electronics. iDrive series are for torque, speed and/or position control, while sDrive series are for high performance variable or fixed speed operation.

EnduraMax brushless DC motors are best suited for commercial and industrial applications such as AGV vehicle traction or steering, medical patient-handling equipment, mobile HVAC blowers and fans, rotary/linear actuators, and material handling systems.

EnduraMax series capabilities are summarized below.